FABRICATION

FABRICATION

STANDIS combines its superior engineering capability with its manufacturing partners, offering you high quality products that you have never had before.

Consistent high-quality weld every time, means you can have peace of mind in the durability, safety, and efficiency of your project like never before. The level of accuracy and quality control that can be achieved with our welding process is unmatched, and with the help of our team of experts, you can rest assured your project will be successful.

Competencies

Competencies

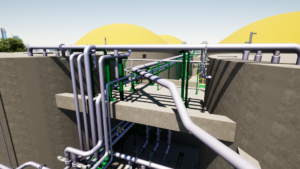

- Pipe Spooling

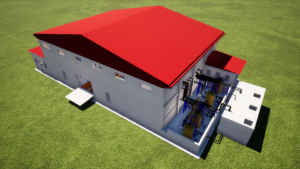

- Skid Assembly

- Module Assembly

- NDE Testing

- Hydrotesting

- Carbon Steel

- Stainless Steel

- Inconel 625

- Monel 400

- Structural Steel

- Glass Lined

- Fibreglass Reinforced

Personnel

Personnel

- Journeyman Pipefitters

- Pipefitter Apprentices

- CWB Structural Welders

- Rig Welders – B Pressure (CS)

- Rig Welders – B Pressure (SS)

- Welder Apprentices

- Welding Foremen

- Level 1 & 2 CSA 178.2 Visual

- Weld Inspectors

Resources

Resources

- Piping Capacity 750 FDI/day

- 33,000 SQFT Shop

- 4 Acre Yard

- Heated Mod Assembly Bay

- 2 Robotic Spool Welders

- 10 Welding Bays

- NDE Bunker

- Digital Inspection

- Digital Spool Verification

WELDING PROCEDURES COVERING - P1 – P1 Groups 1 & 2 (Carbon Steel)

- WPS’s without PWHT and with PWHT

- P8 to P8 Group 1 (Stainless Steel)

- P42 to P42 (Monel Alloys)

- P43 to P43 (Inconel Alloys)

Let's Work Together

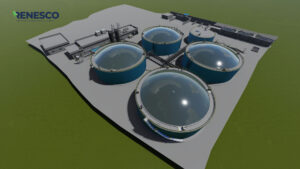

PROJECTS

PROJECTS

- All

- AUTOMATION SYSTEM

- CONSULTANCY

- DESIGN & DRAFTING

- FABRICATION